ELECTRICAL ENGINEERING | CIRCUITS | ALTERNATING CURRENT | DIRECT CURRENT | GENERATION | TRANSMISSION LINES | PROTECTIVE RELAYING | SUBSTATION | SCADA | DISTRIBUTION SYSTEM | POWER SYSTEM | FAULT ANALYSIS

Showing posts with label Power Quality. Show all posts

Showing posts with label Power Quality. Show all posts

WHAT IS POWER QUALITY?

There can be completely different definitions for power quality, depending on one’s frame of reference. For example, a utility may define power quality as reliability and show statistics demonstrating that its system is 99.98 percent reliable.

Criteria established by regulatory agencies are usually in this vein. A manufacturer of load equipment may define power quality as those characteristics of the power supply that enable the equipment to work properly. These characteristics can be very different for different criteria.

Power quality is ultimately a consumer-driven issue, and the end user’s point of reference takes precedence Therefore, the following definition of a power quality problem is used:

"Any power problem manifested in voltage, current, or frequency deviations that results in failure or misoperation of customer equipment."

There are many misunderstandings regarding the causes of power quality problems. The utility’s and

customer’s perspectives are often much different. While both tend to blame about two-thirds of the events on natural phenomena (e.g., lightning), customers, much more frequently than utility personnel, think that the utility is at fault.

When there is a power problem with a piece of equipment, end users may be quick to complain to the utility of an “outage” or “glitch” that has caused the problem. However, the utility records may indicate no abnormal events on the feed to the customer.

We recently investigated a case where the end-use equipment was knocked off line 30 times in 9 months, but there were only five operations on the utility substation breaker. It must be realized that there are many events resulting in end-user problems that never show up in the utility statistics.

One example is capacitor switching, which is quite common and normal on the utility system, but can cause transient overvoltages that disrupt manufacturing machinery.

Another example is a momentary fault elsewhere in the system that causes the voltage to sag briefly at the location of the customer in question. This might cause an adjustable-speed drive or a distributed

generator to trip off, but the utility will have no indication that anything was amiss on the feeder unless it has a power quality monitor installed.

In addition to real power quality problems, there are also perceived power quality problems that may actually be related to hardware, software, or control system malfunctions. Electronic components can degrade over time due to repeated transient voltages and eventually fail due to a relatively low magnitude event.

Thus, it is sometimes difficult to associate a failure with a specific cause. It is becoming more common that designers of control software for microprocessor-based equipment have an incomplete knowledge of how power systems operate and do not anticipate all types of malfunction events.

Thus, a device can misbehave because of a deficiency in the embedded software. This is particularly common with early versions of new computer-controlled load equipment.

One of the main objectives of this site is to educate utilities, end users, and equipment suppliers alike to reduce the frequency of malfunctions caused by software deficiencies.

In response to this growing concern for power quality, electric utilities have programs that help them respond to customer concerns. The philosophy of these programs ranges from reactive, where the utility responds to customer complaints, to proactive, where the utility is involved in educating the customer and promoting services that can help develop solutions to power quality problems.

The regulatory issues facing utilities may play an important role in how their programs are structured. Since power quality problems often involve interactions between the supply system and the customer facility and equipment, regulators should make sure that distribution companies have incentives to work with customers and help customers solve these problems.

The economics involved in solving a power quality problem must also be included in the analysis. It is not always economical to eliminate power quality variations on the supply side.

In many cases, the optimal solution to a problem may involve making a particular piece of sensitive equipment less sensitive to power quality variations. The level of power quality required is that level which will result in proper operation of the equipment at a particular facility.

Power quality, like quality in other goods and services, is difficult to quantify. There is no single accepted definition of quality power. There are standards for voltage and other technical criteria that may be measured, but the ultimate measure of power quality is determined by the performance and productivity of end-user equipment.

If the electric power is inadequate for those needs, then the “quality” is lacking. Perhaps nothing has been more symbolic of a mismatch in the power delivery system and consumer technology than the “blinking clock” phenomenon.

Clock designers created the blinking display of a digital clock to warn of possible incorrect time after loss of power and inadvertently created one of the first power quality monitors. It has made the homeowner aware that there are numerous minor disturbances occurring throughout the power delivery system that may have no ill effects other than to be detected by a clock.

Many appliances now have a built-in clock, so the average household may have about a dozen clocks that must be reset when there is a brief interruption. Older-technology motor-driven clocks would simply lose a few seconds during minor disturbances and then promptly come back into synchronism.

WHAT IS POWER QUALITY ALL ABOUT? BASIC INFORMATION

Electric power quality has emerged as a major area of electric power engineering. The predominant reason for this emergence is the increase in sensitivity of end-use equipment. The various aspects of power quality as it impacts utility companies and their customers and includes material on (1) grounding, (2) voltage sags, (3) harmonics, (4) voltage flicker, and (5) long-term monitoring.

While these five topics do not cover all aspects of power quality, they provide the reader with a broad based overview that should serve to increase overall understanding of problems related to power quality.

Proper grounding of equipment is essential for safe and proper operation of sensitive electronic equipment. In times past, it was thought by some that equipment grounding as specified in the U.S. By the National Electric Code was in contrast with methods needed to insure power quality.

Since those early times, significant evidence has emerged to support the position that, in the vast majority of instances, grounding according to the National Electric Code is essential to insure proper and trouble free equipment operation, and also to insure the safety of associated personnel.

Other than poor grounding practices, voltage sags due primarily to system faults are probably the most significant of all power quality problems. Voltage sags due to short circuits are often seen at distances very remote from the fault point, thereby affecting a potentially large number of utility customers.

Coupled with the wide-area impact of a fault event is the fact that there is no effective preventive for all power system faults. End-use equipment will, therefore, be exposed to short periods of reduced voltage which may or may not lead to malfunctions.

Like voltage sags, the concerns associated with flicker are also related to voltage variations. Voltage flicker, however, is tied to the likelihood of a human observer to become annoyed by the variations in the output of a lamp when the supply voltage amplitude is varying.

In most cases, voltage flicker considers (at least approximately) periodic voltage fluctuations with frequencies less than about 30–35 Hz that are small in size. Human perception, rather than equipment malfunction, is the relevant factor when considering voltage flicker.

For many periodic waveform (either voltage or current) variations, the power of classical Fourier series theory can be applied. The terms in the Fourier series are called harmonics; relevant harmonic terms may have frequencies above or below the fundamental power system frequency.

In most cases, non fundamental frequency equipment currents produce voltages in the power delivery system at those same frequencies. This voltage distortion is present in the supply to other end-use equipment and can lead to improper operation of the equipment.

Harmonics, like most other power quality problems, require significant amounts of measured data in order for the problem to be diagnosed accurately. Monitoring may be short- or long-term and may be relatively cheap or very costly and often represents the majority of the work required to develop power

quality solutions.

In summary, the power quality problems associated with grounding, voltage sags, harmonics, and voltage flicker are those most often encountered in practice. It should be recognized that the voltage and current transients associated with common events like lightning strokes and capacitor switching can also negatively impact end-use equipment.

FERRORESONANCE – POWER QUALITY ISSUE BASIC AND TUTORIALS

The term ferroresonance refers to a resonance that involves capacitance and iron-core inductance. The most common condition in which it causes disturbances in the power system is when the magnetizing impedance of a transformer is placed in series with a system capacitor due to an open-phase conductor.

Under controlled conditions, ferroresonance can be exploited for useful purpose such as in a constant voltage transformer. In practice, ferroresonance most commonly occurs when unloaded transformers become isolated on underground cables of a certain range of lengths.

The capacitance of overhead distribution lines is generally insufficient to yield the appropriate conditions. The minimum length of cable required to cause ferroresonance varies with system voltage level.

The capacitance of cables is nearly the same for all distribution voltage levels, varying from 40 to 100 nF per 1000 ft, depending on conductor size. However, the magnetizing reactance of a 35-kVclass distribution transformer is several times higher (curve is steeper) than a comparably-sized 15-kV-class transformer.

Therefore, damaging ferroresonance has been more common at the higher voltages. For delta connected transformers, ferroresonance can occur for less than 100 ft of cable.

For this reason, many utilities avoid this connection on cable-fed transformers. The grounded wyewye transformer has become the most commonly used connection in underground systems in North America.

It is more resistant, but not immune, to ferroresonance because most units use a three legged or five legged core design that couples the phases magnetically. It may require a minimum of several hundred feet of cable to provide enough capacitance to create a ferroresonant condition for this connection.

The most common events leading to ferroresonance are

• Manual switching of an unloaded, cable-fed, 3-phase transformer where only one phase is closed (Fig. 23-28a). Ferroresonance may be noted when the first phase is closed upon energization or before the last phase is opened on de-energization.

• Manual switching of an unloaded, cable-fed, 3-phase transformer where one of the phases is open (Fig. 23-28b). Again, this may happen during energization or de-energization.

• One or two riser-pole fuses may blow leaving a transformer with one or two phases open. Single phase reclosers may also cause this condition. Today, many modern commercial loads will have controls that transfer the load to backup systems when they sense this condition. Unfortunately, this leaves the transformer without any load to damp out the resonance.

• Phase of a cable connected to a wye-connected transformer.

FIGURE 23-28 Common system conditions where ferroresonance may occur: (a) one phase closed, (b) one phase open.

MITIGATION EQUIPMENT FOR VOLTAGE SAGS POWER QUALITY PROBLEM

The most commonly applied method of mitigation is the installation of additional equipment at the system-equipment interface. Also recent developments point toward a continued interest in this way of mitigation.

The popularity of mitigation equipment is explained by it being the only place where the customer has control over the situation. Both changes in the supply as well as improvement of the equipment are often completely outside of the control of the end user. Some examples of mitigation equipment are:

. Uninterruptable power supply (UPS). This is the most commonly used device to protect lowpower equipment (computers, etc.) against voltage sags and interruptions. During the sag or interruption, the power supply is taken over by an internal battery.

The battery can supply the load for, typically, between 15 and 30 minutes.

. Static transfer switch. A static transfer switch switches the load from the supply with the sag to another supply within a few milliseconds. This limits the duration of a sag to less than one halfcycle, assuming that a suitable alternate supply is available.

. Dynamic voltage restorer (DVR). This device uses modern power electronic components to insert a series voltage source between the supply and the load. The voltage source compensates for the voltage drop due to the sag.

Some devices use internal energy storage to make up for the drop in active power supplied by the system. They can only mitigate sags up to a maximum duration.

Other devices take the same amount of active power from the supply by increasing the current. These can only mitigate sags down to a minimum magnitude. The same holds for devices boosting the voltage through a transformer with static tap changer.

. Motor-generator sets. Motor-generator sets are the classical solution for sag and interruption mitigation with large equipment. They are obviously not suitable for an office environment but the noise and the maintenance requirements are often no problem in an industrial environment.

Some manufacturers combine the motor-generator set with a backup generator; others combine it with power-electronic converters to obtain a longer ride-through time.

FLICKERING LIGHTS – POWER QUALITY CASE STUDY AND SOLUTION

This case study concerns a residential electrical system. The homeowners were experiencing light flicker when loads were energized and deenergized in their homes.

Background

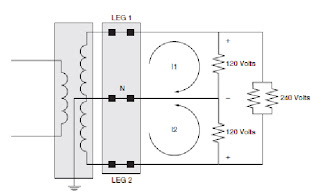

Residential systems are served from single-phase transformers employing a spilt secondary winding, often referred to as a single-phase three-wire system. This type of transformer is used to deliver both 120-volt and 240-volt single-phase power to the residential loads.

The primary of the transformer is often served from a 12 to 15 kV distribution system by the local utility. Figure 29.14 illustrates the concept of a split-phase system.

FIGURE 29.14 Split-phase system serving a residential customer.

When this type of service is operating properly, 120 volts can be measured from either leg to the neutral conductor. Due to the polarity of the secondary windings in the transformer, the polarity of each 120-volt leg is opposite the other, thus allowing a total of 240 volts between the legs as illustrated.

The proper operation of this type of system is dependent on the physical connection of the neutral conductor or center tap of the secondary winding. If the neutral connection is removed, 240 volts will remain across the two legs, but the line-to-neutral voltage for either phase can be shifted, causing either a low or high voltage from line to neutral.

Most loads in a residential dwelling, i.e., lighting, televisions, microwaves, home electronics, etc., are operated from 120 volts. However, there are a few major loads that incorporate the use of the 240 volts available. These loads include electric water heaters, electric stoves and ovens, heat pumps, etc.

The Problem

In this case, there were problems in the residence that caused the homeowner to question the integrity of the power system serving his home. On occasion, the lights would flicker erratically when the washing machine and dryer were operating at the same time. When large single-phase loads were operated, low power incandescent light bulb intensity would flicker.

Measurements were performed at several 120-volt outlets throughout the house. When the microwave was operated, the voltage at several of the 120-volt outlets would increase from 120 volts nominal to 128 volts.

The voltage would return to normal after the microwave was turned off. The voltage would also increase when a 1500-Watt space heater was operated. It was determined that the voltage would decrease to approximately 112 volts on the leg from which the large load was served. After the measurements confirmed suspicions of high and low voltages during heavy load operation, finding the source of the problem was the next task at hand.

The hunt began at the service entrance to the house. A visual inspection was made of the meter base and socket after the meter was removed by the local utility. It was discovered that one of the neutral connectors was loose. While attempting to tighten this connector, the connector fell off of the meter socket into the bottom of the meter base (see Fig. 29.15).

FIGURE 29.15 Actual residential meter base. Notice the missing neutral clamp on load side of meter.

Could this loose connector have been the cause of the flickering voltage? Let’s examine the effects of the loose neutral connection. Figures 29.16 and 29.17 will be referred to several times during this discussion.

Under normal conditions with a solid neutral connection (Fig. 29.16), load current flows through each leg and is returned to the source through the neutral conductor. There is very little impedance in either the hot or the neutral conductor; therefore, no appreciable voltage drop exists.

FIGURE 29.16 The effects of a solid neutral connection in the meter base.

When the neutral is loose or missing, a significant voltage can develop across the neutral connection in the meter base, as illustrated in Fig. 29.17. When a large load is connected across Leg 1 to N and the other leg is lightly loaded (i.e., Leg 1 to N is approximately 10 times the load on Leg 2 to N), the current flowing through the neutral will develop a voltage across the loose connection.

This voltage is in phase with the voltage from Leg 1 to N0 (see Fig. 29.17) and the total voltage from Leg 1 to N will be 120 volts.

FIGURE 29.17 The effects of a loose neutral connection in the meter base.

However, the voltage supplied to any loads connected from Leg 2 to N0 will rise to 128 volts, as illustrated in Fig. 29.17. The total voltage across the Leg 1 and Leg 2 must remain constant at 240 volts. It should be noted that the voltage from Leg 2 to N will be 120 volts since the voltage across the loose connection is 1808 out of phase with the Leg 2 to N0 voltage.

Therefore, with the missing neutral connection, the voltage from Leg 2 to N0 would rise, causing the light flicker. This explains the rise in voltage when a large load was energized on the system.

The Solution

The solution in this case was simple—replace the failed connector.

Conclusions

Over time, the neutral connector had become loose. This loose connection caused heating, which in turn caused the threads on the connector to become worn, and the connector failed.

After replacing the connector in the meter base, the flickering light phenomena disappeared. On systems of this type, if a voltage rise occurs when loads are energized, it is a good indication that the neutral connection may be loose or missing.

IEEE STANDARDS 519 AND 1159 – POWER QUALITY STANDARDS

IEEE Standards are publications that provide acceptable design practice. IEEE Standards addressing power quality include those defining acceptable power quality (IEEE Standard 519) and another standard relating to the measurement of power-quality “events” (IEEE Standard 1159).

Both of these standards focus on AC systems and their harmonics (that is, multiples of the line frequency). IEEE Standard 519 [2.1] (denoted IEEE Std. 519-1992) is titled “IEEE Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems.”

The abstract of this standard notes that power conversion units are being used today in industrial and commercial facilities, and there are challenges associated with harmonics and reactive power control of such systems. The standard covers limits to the various disturbances recommended to the power distribution system.

The 1992 standard is a revision of an earlier IEEE work published in 1981 covering harmonic control. The basic themes of IEEE Standard 519 are twofold. First, the utility has the responsibility to produce good quality voltage sine waves.Secondly, end-use customers have the responsibility to limit the harmonic currents their circuits draw from the line.

Shown in Figure 2.1 is a utility system feeder serving two customers. The utility source has resistance R and line reactance jXs. The resistance and reactance model the impedances of the utility source, any transformers and switchgear, and power cabling.

Figure 2.1 Harmonic-generating load causing voltage distortion at the point of common coupling (PCC). The AC source is modeled as an ideal voltage source in series with a resistance Rs and a reactance jXs.

Customer #1 on the line draws harmonic current Ih, as shown, perhaps by operating adjustable speed drives, arc furnaces, or other harmonic-creating systems. The voltage Customer #2 sees at the service entrance is the voltage at the “point of common coupling,” often abbreviated as “PCC.” The harmonics drawn by Customer #1 cause voltage distortion at the PCC, due to the voltage drop in the line resistance and reactance due to the harmonic current.

The voltage harmonic distortion limits apply to the quality of the power the utility must deliver to the customer. For instance, for systems of less than 69 kV, IEEE 519 requires limits of 3 percent harmonic distortion for an individual frequency component and 5 percent for total harmonic.

The current harmonic distortion limits apply to limits of harmonics that loads should draw from the utility at the PCC. Note that the harmonic limits differ based on the ISC/IL rating, where ISC is the maximum short-circuit current at the PCC, and IL is the maximum demand load current at the PCC. IEEE Standard 1159 [2.2] is entitled “IEEE Recommended Practice for Monitoring Electric Power Quality,” and as its title suggests, this standard covers recommended methods of measuring power quality events.

Many different types of power-quality measurement devices exist and it is important for workers in different areas of power distribution, transmission, and processing to use the same language and measurement techniques. In future chapters, we draw extensively from IEEE Standards 519 and 1159. distortion.

PULSE WIDTH MODULATION TECHNIQUE FOR POWER QUALITY

PWM is used in inverters to supply power to the ac motors more commonly in the industry now. In PWM, a sawtooth wave is used to modulate the chops as shown in Figure 4.8.

FIGURE 4.8 The principle of pulse-width modulation (PWM). (From Arrillaga, J., Bradley, J.D., and Bodger, P. (1985), Power System Harmonics, John Wiley, Chichester, U.K. With permission.)

The sawtooth wave has a frequency that is a multiple of three times the sine-wave frequency, allowing symmetrical three-phase voltages to be generated from a three phase sine-wave set and one sawtooth waveform. The PWM control signal is generated by feeding the sawtooth carrier signal and sine-wave modulating signal to a comparator circuit. In this simple form, this method controls line-to-line voltage from zero to full voltage by increasing the magnitude of the sawtooth, with little regard to the harmonics generated.

More efficient PWM techniques have been developed to control the fundamental and harmonic voltages simultaneously. Using suitable switching times with five on/off actions per cycle, one can eliminate both fifth and seventh harmonics together.

Generally, at any fundamental switching frequency, each chop per half-cycle of the inverter phase voltage waveform can eliminate one harmonic of the waveform or reduce a group of harmonic amplitudes. Assuming that there are m chops per half-cycle, one chop can be utilized to control the fundamental voltage and the other (m - 1) to reduce the other specified low-order harmonics or to minimize power losses caused by a specified range of harmonics within the motors.

However, it must be noted that, as the total rms harmonic voltage cannot change, the portion of the rms voltage that was provided by the elimination of harmonics will be spread over the remaining harmonic magnitudes. Hence, the motor designer must take this fact into account.

Also, the integrating filter characteristic of the motor will reduce some of these higher-order-current harmonics. Because of the number of switchings, the usable fundamental rating and the converter efficiency are reduced as GTOs require significant energy (resulting in increased thyristor losses and heating effects) for each switching operation.

In contrast, devices such as IGBTs (Integrated state Bipolar Transistors) and IGCTs (Integrated State Commutated Thyrestors) require much lower switching energy and are better suited to the use of PWM techniques. However, with the use of chain circuits that require reduced switching frequency, that is, once per two cycles of frequency, high-power inverters can be constructed using GTOs.

POWER QUALITY DATA COLLECTION BASIC INFORMATION

To develop compatibility levels and to deepen the understanding of system performance, data on power quality are being collected by various agencies from around the world. Some of these organizations are Electrical Power Research Institute (EPRI), Canadian Electrical Association, National Power Laboratories (Necedah, Wisconsin), Norwegian Electric Power Research Institute, International Union of Producers and Distributors of Electrical Energy (UNIPEDE), Electricite de France, Northeast Utilities Service (Berlin, Connecticut), East Midlands Electricity (EME, Nottingham, England), and Consolidated Edison Company of New York, Inc.

Because of reasons of cost, power quality monitoring is still in its infancy. However, as a result of deregulation in the utility industry in many countries, they will be forced to compete for customers.

One of the ways in which they can achieve this is by monitoring power quality and showing the customers that their power supply reliability is better than that of their competitors. Hence, utilities on their own are likely to undertake more monitoring of the feeders supplying their major customers. The data required to monitor power quality are usually voluminous.

Hence, software must be used to automatically characterize measured events and store the results in a well-defined database. It will be economical to integrate the data collected from power quality and in plant monitoring with electric power instrumentation, site descriptions, and event information. For details of a power quality database management and analysis system called PQView, developed by Electrotek Concepts, Inc. (Knoxville, Tennessee).

Over the last several years, the EPRI and one of its contractors (Electrotek Concepts, Inc.) have been developing a vendor-independent interchange format for power quality-related information. For the details of this Power Quality Data Interchange Format (PQDIF), PQView, and PQWeb systems.

In 1996, EPRI and Electrotek placed PQDIF in the public domain to facilitate the interchange of power quality data between interested parties. EPRI and Electrotek have also offered the format, sample source code, and documentation to the IEEE 1159.3 task force as a possible initial format to meet that group’s requirements.

In 1991, the Power System Relaying Committee of the IEEE Power Engineering Society developed the standard C37.111.39 The main purpose of this standard was to define a common format for the data files and exchange medium needed for the interchange of various types of fault, test, or simulation data.

Among others, the standard defines as sources of data the following: digital fault recorders, analog tape recorders, digital protective relays, transient simulation programs, and analog simulators. For the details of indices for assessing the harmonic distortion of power quality, D. Daniel Sabin et al.

A power quality database can provide a basis for developing equipment compatibility specifications and guidelines for future equipment enhancements. In addition, a database of the causes for recorded disturbances can be used to make system improvements.

By ensuring equipment compatibility, safety hazards resulting from equipment misoperation or failure can be avoided. Performance indices that measure system reliability in terms of voltage outages are defined in a document (Reference 31) prepared by the EPRI, Palo Alto, California.

POWER QUALITY IMPROVEMENT TECHNIQUES

A List Of Techniques To Improve Power Quality

Nonlinear loads produce harmonic currents that can propagate to other locations in the power system and eventually return back to the source. Therefore, harmonic current propagation produces harmonic voltages throughout the power systems.

Many mitigation techniques have been proposed and implemented to maintain the harmonic voltages and currents within recommended levels:

1. high power quality equipment design,

2. harmonic cancellation,

3. dedicated line or transformer,

4. optimal placement and sizing of capacitor banks,

5. derating of power system devices, and

6. harmonic filters (passive, active, hybrid) and custom power devices such as active power line conditioners (APLCs) and unified or universal power quality conditioners (UPQCs).

The practice is that if at PCC harmonic currents are not within the permissible limits, the consumer with the nonlinear load must take some measures to comply with standards.

However, if harmonic voltages are above recommended levels- and the harmonic currents injected comply with standards - the utility will have to take appropriate actions to improve the power quality.

TYPES OF WAVEFORM DISTORTION BASIC INFORMATION AND TUTORIALS

Waveform distortion is defined as a steady-state deviation from an ideal sine wave of power frequency principally characterized by the spectral content of the deviation.

There are five primary types of waveform distortion:

■ DC offset

■ Harmonics

■ Interharmonics

■ Notching

■ Noise

DC offset. The presence of a dc voltage or current in an ac power system is termed dc offset. This can occur as the result of a geomagnetic disturbance or asymmetry of electronic power converters. Incandescent light bulb life extenders, for example, may consist of diodes that reduce the rms voltage supplied to the light bulb by half-wave rectification.

Direct current in ac networks can have a detrimental effect by biasing transformer cores so they saturate in normal operation. This causes additional heating and loss of transformer life. Direct current may also cause the electrolytic erosion of grounding electrodes and other connectors.

Harmonics. Harmonics are sinusoidal voltages or currents having frequencies that are integer multiples of the frequency at which the supply system is designed to operate (termed the fundamental frequency; usually 50 or 60 Hz). Periodically distorted waveforms can be decomposed into a sum of the fundamental frequency and the harmonics.

Harmonic distortion originates in the nonlinear characteristics of devices and loads on the power system. Harmonic distortion levels are described by the complete harmonic spectrum with magnitudes and phase angles of each individual harmonic component. It is also common to use a single quantity, the total harmonic distortion (THD), as a measure of the effective value of harmonic distortion.

Current distortion levels can be characterized by a THD value, as previously described, but this can often be misleading. For example, many adjustable-speed drives will exhibit high THD values for the input current when they are operating at very light loads. This is not necessarily a significant concern because the magnitude of harmonic current is low, even though its relative distortion is high.

To handle this concern for characterizing harmonic currents in a consistent fashion, IEEE Standard 519-1992 defines another term, the total demand distortion (TDD). This term is the same as the total harmonic distortion except that the distortion is expressed as a percent of some rated load current rather than as a percent of the fundamental current magnitude at the instant of measurement. IEEE Standard 519-1992 provides guidelines for harmonic current and voltage distortionlevels on distribution and transmission circuits.

Interharmonics. Voltages or currents having frequency components that are not integer multiples of the frequency at which the supply system is designed to operate (e.g., 50 or 60 Hz) are called interharmonics. They can appear as discrete frequencies or as a wideband spectrum. Interharmonics can be found in networks of all voltage classes.

The main sources of interharmonic waveform distortion are static frequency converters, cycloconverters, induction furnaces, and arcing devices. Power line carrier signals can also be considered as interharmonics. There is now a better understanding of the origins and effects of interharmonic distortion.

It is generally the result of frequency conversion and is often not constant; it varies with load. Such interharmonic currents can excite quite severe resonances on the power system as the varying interharmonic frequency becomes coincident with natural frequencies of the system. They have been shown to affect power-line-carrier signaling and induce visual flicker in fluorescent and other arc lighting as well as in computer display devices.

Notching. Notching is a periodic voltage disturbance caused by the normal operation of power electronic devices when current is commutated from one phase to another. Since notching occurs continuously, it can be characterized through the harmonic spectrum of the affected voltage.

However, it is generally treated as a special case. The frequency components associated with notching can be quite high and may not be readily characterized with measurement equipment normally used for harmonic analysis.

Noise. Noise is defined as unwanted electrical signals with broadband spectral content lower than 200 kHz superimposed upon the power system voltage or current in phase conductors, or found on neutral conductors or signal lines.

Noise in power systems can be caused by power electronic devices, control circuits, arcing equipment, loads with solid-state rectifiers, and switching power supplies. Noise problems are often exacerbated by improper grounding that fails to conduct noise away from the power system.

Basically, noise consists of any unwanted distortion of the power signal that cannot be classified as harmonic distortion or transients. Noise disturbs electronic devices such as microcomputer and programmable controllers. The problem can be mitigated by using filters, isolation transformers, and line conditioners.

HARMONICS IN POWER SYSTEM – WHAT ARE POWER HARMONICS?

Power system harmonics are not a new topic, but the proliferation of high-power electronics used in motor drives and power controllers has necessitated increased research and development in many areas relating to harmonics.

For many years, high-voltage direct current (HVDC) stations have been a major focus area for the study of power system harmonics due to their rectifier and inverter stations. Roughly two decades ago, electronic devices that could handle several kW up to several MW became commercially viable and reliable products.

This technological advance in electronics led to the widespread use of numerous converter topologies, all of which represent nonlinear elements in the power system.

Even though the power semiconductor converter is largely responsible for the large-scale interest in power system harmonics, other types of equipment also present a nonlinear characteristic to the power system. In broad terms, loads that produce harmonics can be grouped into three main categories covering (1) arcing loads, (2) semiconductor converter loads, and (3) loads with magnetic saturation of iron cores.

Arcing loads, like electric arc furnaces and florescent lamps, tend to produce harmonics across a wide range of frequencies with a generally decreasing relationship with frequency. Semiconductor loads, such as adjustable-speed motor drives, tend to produce certain harmonic patterns with relatively predictable amplitudes at known harmonics.

Saturated magnetic elements, like overexcited transformers, also tend to produce certain ‘‘characteristic’’ harmonics. Like arcing loads, both semiconductor converters and saturated magnetics produce harmonics that generally decrease with frequency.

Regardless of the load category, the same fundamental theory can be used to study power quality problems associated with harmonics. In most cases, any periodic distorted power system waveform (voltage, current, flux, etc.) can be represented as a series consisting of a DC term and an infinite sum of sinusoidal terms.

A vast amount of theoretical mathematics has been devoted to the evaluation of the terms in the infinite sum, but It is reasonable to presume that instrumentation is available that will provide both the magnitude Fi and the phase angle ui for each term in the series. Taken together, the magnitude and phase of the ith term completely describe the ith harmonic.

It should be noted that not all loads produce harmonics that are integer multiples of the power frequency. These noninteger multiple harmonics are generally referred to as interharmonics and are commonly produced by arcing loads and cycloconverters.

All harmonic terms, both integer and noninteger multiples of the power frequency, are analytically treated in the same manner, usually based on the principle of superposition.

STATIC COMPENSATOR (STATCOM) DEFINITION BASIC AND TUTORIALS

This is a shunt device that does not require passive elements like inductors and capacitors. The schematic diagram of a SMIB power system that is compensated by a shunt compensator is shown in Figure 1.10. The STATCOM is built around a voltage source inverter, which is supplied by a dc capacitor. The inverter consists of GTO switches which are turned on and off through a gate drive circuit.

The output of the voltage source inverter is connected to that ac system through a coupling transformer. The inverter produces a quasi sinewave voltage Vo at the fundamental frequency. Let us assume that the losses in the inverter and the coupling transformer are negligible.

The inverter is then gated such that the output voltage of the inverter Vo is in phase with the local bus voltage v. In this situation two ac voltages that are in phase are connected together through a reactor, which is the leakage reactance of the coupling transformer.

Therefore the current ['I is a purely reactive. If the magnitude of the voltage Vm is more than that of the voltage Vo, the reactive current Iq flows from the bus to the inverter. Then the inverter will consume reactive power.

If, on the other hand, the magnitude of Vo is greater than that of Vm, then the inverter feeds reactive power to the system. Therefore through this arrangement the STATCOM can generate or absorb reactive power.

In practice how ever the losses are not negligible and must be drawn from the ac system. This is accomplished by slightly shifting the phase angle of the voltage Vo through a feedback mechanism such that the de capacitor voltage is held constant.

The structure of the GTO-based VSI must be so chosen that the lower order harmonics are eliminated from the output voltage. The VSI will then resemble a synchronous voltage source. Because the switching frequency of each GTOs must be kept low, overall switch ripple needs to be kept low without use of PWM.

This is accomplished by connecting a large number of basic inverter modules. The construction of a 48-step voltage source inverter is discussed in [19].

In this inverter, eight identical elementary 6-step inverters are operated from a common dc bus. Each of these 6-step inverters produces a compatible set of three-phase, quasi-square wave output voltage waveforms.

The outputs of these 6-step inverters are added through a magnetic circuit that contains eighteen single phase three winding transformers and six single-phase two winding transformers. This connection eliminates all low-order harmonics.

The lowest order harmonic on the ac side is 47th while that on the dc side is 48th . The line-to-line output\ voltage of the 48-step inverter is shown in Figure 1.11 along with the fundamental voltage. It can be seen that the output is a stepped approximation of the fundamental sinewave. The construction of a multilevel synchronous voltage source is given in.

CBEMA AND ITIC CURVES POWER QUALITY INFORMATION

POWER QUALITY - CBEMA AND ITIC CURVES

CBEMA and ITI Curves

CBEMA curve is one of the most frequently employed displays of data to represent the

power quality. A portion of the curve adapted from IEEE Standard 4469 that we typically use in our analysis of power quality monitoring results is shown in below.

In the CBEMA Curve, the axes represent magnitude and duration of the event. Points below the envelope are presumed to cause the load to drop out due to lack of energy. Points above the envelope are presumed to cause other malfunctions such as insulation failure, overvoltage trip, and overexcitation.

The upper curve is actually defined down to 0.001 cycle where it has a value of about 375 percent voltage. We typically employ the curve only from 0.1 cycle and higher due to limitations in power quality monitoring instruments and differences in opinion over defining the magnitude values in the subcycle time frame.

Computer equipment sensitivity to sags and swells can be charted in curves of acceptable sag/swell amplitude versus event duration. This curve was originally developed by CBEMA (Computer Business Equipment Manufacturers Association) to describe the tolerance of mainframe computer equipment to the magnitude and duration of voltage variations on the power system.

While many modern computers have greater tolerance than this, the curve has become a standard design target for sensitive equipment to be applied on the power system and a common format for reporting power quality variation data.

In the 1970s, the (CBEMA) developed the curve [2.5] of Figure 2.5 utilizing historical data from mainframe computer operations, showing the range of acceptable power supply voltages for computer equipment.

The horizontal axis shows the duration of the sag or swell, and the vertical axis shows the percent change in line voltage.

In addition, the IEEE has addressed sag susceptibility and the economics of sag-induced events in IEEE Std. 1346–1998 [2.6]. This document includes measured power quality data taken from numerous sites.

The original CBEMA curve was originally developed by the Computers Business Equipment Manufacturers Association (CBEMA) and adopted by IEEE Standard 446. CBEMA has been renamed as the Information Technology Industry (ITI) Council, and a new curve as shown in Figure 1.1 has been developed to replace the original CBEMA curve.

The modified curve has been developed that specifically applies to common 120-V computer equipment. The concept is similar to the CBEMA curve. Although developed for 120-V computer equipment, the curve has been applied to general power quality evaluation like its predecessor curve.

Outside the bounded tolerance region, in the no-damage region, the applied voltages are very low, and sensitive computer equipment will not function properly; however, no damage occurs to the equipment.

In the prohibited region, sensitive computer equipment will be damaged due to the occurrence of severe voltage swells.

Both the CBEMA and ITI curves were specially developed for use in the 60-Hz 120-V distribution voltage system. The guidelines expect users in 50-Hz 240-V distribution systems to exercise their own judgment when applying the CBEMA and ITI curves.

Although there is no legal requirement to conform to these curves, most original equipment manufacturers build equipment that meet or exceed the limits set forth by these curves, with the occasional exception.

That is the value of CBEMA and ITIC Curves.

EXAMPLES OF POOR POWER QUALITY

POOR POWER QUALITY EXAMPLES

Poor power quality is usually identified in the “powering” part of the definition, namely in the deviations in the voltage waveform from the ideal. A set of waveforms for typical power disturbances is shown in Figure 1.5. These waveforms are either (a) observed, (b) calculated, or (c) generated by test equipment.

■ A voltage sag (also called a “dip”9) is a brief decrease in the rms linevoltage of 10 to 90 percent of the nominal line-voltage. The duration of a sag is 0.5 cycle to 1 minute [1.44–1.50]. Common sources of sags are the starting of large induction motors and utility faults.

■ A voltage swell is the converse to the sag. A swell is a brief increase in the rms line-voltage of 110 to 180 percent of the nominal line-voltage for a duration of 0.5 cycle to 1 minute. Sources of voltage swells are line

faults and incorrect tap settings in tap changers in substations.

■ An impulsive transient is a brief, unidirectional variation in voltage, current, or both on a power line. The most common causes of impulsive transients are lightning strikes, switching of inductive loads, or switching in the power distribution system. These transients can result in equipment shutdown or damage if the disturbance level is high enough. The effects of transients can be mitigated by the use of transient voltage suppressors such as Zener diodes and MOVs (metal-oxide varistors).

■ An oscillatory transient is a brief, bidirectional variation in voltage, current, or both on a power line. These can occur due to the switching of power factor correction capacitors, or transformer ferroresonance.

■ An interruption is defined as a reduction in line-voltage or current to less than 10 percent of the nominal, not exceeding 60 seconds in length.

■ Another common power-quality event is “notching,” which can be created by rectifiers that have finite line inductance. The notches show up due to an effect known as “current commutation.”

■ Voltage fluctuations are relatively small (less than 5 percent) variations in the rms line-voltage. These variations can be caused by cycloconverters, arc furnaces, and other systems that draw current not in synchronization with the line frequency [1.51–1.61]. Such fluctuations can result in variations in the lighting intensity due to an effect known as “flicker” which is visible to the end user.

■ A voltage “imbalance” is a variation in the amplitudes of three-phase voltages, relative to one another.

POWER QUALITY = VOLTAGE QUALITY (IS IT?)

The common term for describing the subject of this site is power quality; however, it is actually the quality of the voltage that is being addressed in most cases.

Technically, in engineering terms, power is the rate of energy delivery and is proportional to the product of the voltage and current.

It would be difficult to define the quality of this quantity in any meaningful manner. The power supply system can only control the quality of the voltage; it has no control over the currents that particular loads might draw.

Therefore, the standards in the power quality area are devoted to maintaining the supply voltage within certain limits.

AC power systems are designed to operate at a sinusoidal voltage of a given frequency [typically 50 or 60 hertz (Hz)] and magnitude. Any significant deviation in the waveform magnitude, frequency, or purity

is a potential power quality problem.

Of course, there is always a close relationship between voltage and current in any practical power system. Although the generators may provide a near-perfect sine-wave voltage, the current passing through the impedance of the system can cause a variety of disturbances to the voltage.

For example,

1. The current resulting from a short circuit causes the voltage to sag or disappear completely, as the case may be.

2. Currents from lightning strokes passing through the power system cause high-impulse voltages that frequently flash over insulation and lead to other phenomena, such as short circuits.

3. Distorted currents from harmonic-producing loads also distort the voltage as they pass through the system impedance. Thus a distorted voltage is presented to other end users.

Therefore, while it is the voltage with which we are ultimately concerned, we must also address phenomena in the current to understand the basis of many power quality problems.

Subscribe to:

Posts (Atom)

PREVIOUS ARTICLES

-

▼

2012

(284)

-

▼

December

(12)

- LAMP COLOR TEMPERATURE BASIC INFORMATION AND TUTOR...

- ENERGY SAVING BALLAST BASIC INFORMATION AND TUTORIALS

- MISMATCHING OF FLUORESCENT LAMPS AND BALLASTS BASI...

- FLUORESCENT BALLASTS TYPES BASIC INFORMATION AND T...

- WHAT IS A LUMINAIRE? BASIC INFORMATION AND TUTORIALS

- CLASSIFICATION OF CABLES USED IN SUBSTATION BASIC ...

- SUBSTATION CABLE VOLTAGE RATING BASIC INFORMATION ...

- GROUNDING GRID DESIGN CRITICAL PARAMETERS BASIC IN...

- CAPACITOR INSTALLATION SYSTEMS BENEFITS BASIC INFO...

- NEC RULES FOR CONDUCTORS

- WHAT IS POWER QUALITY?

- WHAT IS POWER QUALITY ALL ABOUT? BASIC INFORMATION

-

▼

December

(12)

Week's Popular

- THE TRANSMISSION AND DISTRIBUTION SYSTEM BASIC AND TUTORIALS

- CAPACITOR EXCITATION SYSTEM OF GENERATORS BASIC AND TUTORIALS

- LAMP COLOR TEMPERATURE BASIC INFORMATION AND TUTORIALS

- SUBSTATION ELECTRICAL BUS AND PARTS CLEARANCES REQUIREMENTS BASIC INFORMATION AND TUTORIALS

- BREAKER AND A HALF SUBSTATION SCHEME – BASIC INFORMATION AND TUTORIALS

- CBEMA AND ITIC CURVES POWER QUALITY INFORMATION

- ADVANTAGES AND DISADVANTAGES OF DIFFERENT SUBSTATION SCHEMES COMPARISON OF CONFIGURATIONS

- ELECTRICAL WIRING DIAGRAM GRAPHIC SYMBOLS BASIC INFORMATION AND TUTORIALS

- CAUSES OF SPARKING AND POOR COMMUTATION OF DC GENERATORS BASIC INFORMATION

- AC GENERATORS COOLING SYSTEM BASIC AND TUTORIALS